Description

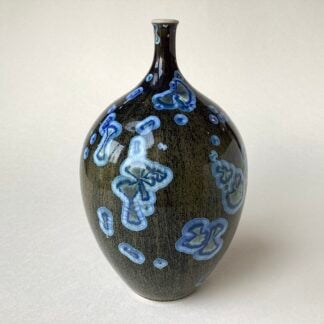

‘Hare’s Fur Crystalline Bottle’

A lovely example of Hare’s Fur glaze on this bottle with distinctive and random blue crystals

Collect from gallery £130

Including UK delivery £140

H 14.4 x W at widest Ø 8.8 cm

Crystalline is a specialist type of glaze where zinc silicate crystals form in the glaze during the kiln firing process. The glaze is mixed using a variety of raw materials, some measured in minute amounts. The firing process uses a complex schedule with several temperature ramps to create different crystal growth formations. The kiln is fired to maximum temperature of around 1300c (cone 10), and then cooled to specific holding temperatures to allow crystals to form in the glaze. The amount of time held at this temperature contributes to the size of the crystals. Crystals occur randomly in the glaze, making each piece unique.

For many years Simon Rich has been producing fine ceramics with his most distinctive glazes from his pottery in West Wales, UK.

Simon had such a strong interest in pottery at an early age that he started when fifteen years old, to teach the craft to his fellow pupils at school.

Upon leaving school, he looked for an outlet for his creative talents and joined the studio of the famous Alan Caiger-Smith at the Aldermarston Pottery. He remained there for five years before establishing himself with a series of exhibitions and shows.

Simon is primarily concerned with creating pleasing shapes and forms. He conjures up images in his mind and turns them over and over until they are ready to be brought into being. He likes to explore the full potential of any one shape, developing it and endeavouring to expand on its creative potential as much as possible. He stops short of extremes, however, as his aim is to create pottery of classical and harmonious beauty.

Simon excels at many techniques including terrasigilata, copper fumed raku, turquoise and azurite glazes and crystalline glazes. In the latter, the zinc crystal glaze is applied to porcelain and is made by melting sand, soda ash, alumina, zinc and flint into a glass compound. It is then ground to a fine powder. Before glazing, an exact amount is weighed out for each pot, and metal oxides are then added to produce the variety of colours that can be seen in the work. The firings vary according to the amount of colourant oxides and glaze adjustments. This produces constantly evolving glazes on the pieces.